A supply-side bonding jumper is installed only at the service, providing a critical connection that ensures electrical safety and system performance. This essential component plays a crucial role in various industries, safeguarding against potential hazards and optimizing electrical operations.

By delving into the intricacies of supply-side bonding jumpers, this comprehensive guide explores their purpose, types, installation techniques, benefits, applications, troubleshooting, and design considerations. Prepare to gain a thorough understanding of this vital electrical component and its significance in ensuring the integrity and reliability of electrical systems.

1. Definition of Supply-Side Bonding Jumper

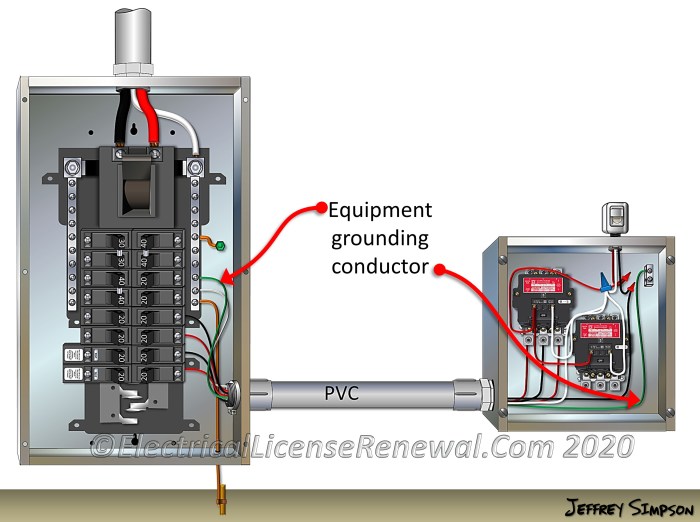

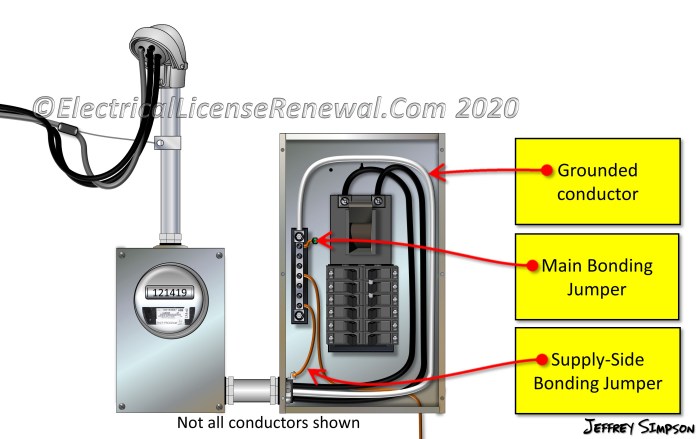

A supply-side bonding jumper is an electrical device used to connect the neutral and ground wires on the supply side of an electrical system. It is typically installed at the service entrance or distribution panel.

The purpose of a supply-side bonding jumper is to ensure that the neutral and ground wires are at the same electrical potential, which helps to prevent electrical shock and equipment damage.

Types of Supply-Side Bonding Jumpers, A supply-side bonding jumper is installed only at the service

- Solid copper

- Flexible copper

- Aluminum

2. Installation of Supply-Side Bonding Jumper

To install a supply-side bonding jumper, follow these steps:

- Turn off the power to the electrical system.

- Remove the cover from the service entrance or distribution panel.

- Locate the neutral and ground wires.

- Connect the bonding jumper to the neutral and ground wires using the appropriate connectors.

- Tighten the connectors securely.

- Replace the cover on the service entrance or distribution panel.

- Turn on the power to the electrical system.

It is important to ensure that the bonding jumper is properly installed and that all connections are tight. Loose connections can lead to electrical problems, including electrical shock and fire.

3. Benefits of Using Supply-Side Bonding Jumper

There are several benefits to using a supply-side bonding jumper, including:

- Prevents electrical shock

- Protects equipment from damage

- Improves system performance

- Reduces the risk of electrical fires

4. Applications of Supply-Side Bonding Jumper

Supply-side bonding jumpers are commonly used in a variety of applications, including:

- Residential buildings

- Commercial buildings

- Industrial facilities

- Electrical substations

5. Troubleshooting Supply-Side Bonding Jumper Issues

If you are experiencing electrical problems, it is possible that the supply-side bonding jumper is not properly installed or is damaged. Some common problems include:

- Electrical shock

- Equipment damage

- System performance issues

- Electrical fires

If you suspect that the supply-side bonding jumper is causing problems, you should have it inspected by a qualified electrician.

6. Design Considerations for Supply-Side Bonding Jumper: A Supply-side Bonding Jumper Is Installed Only At The Service

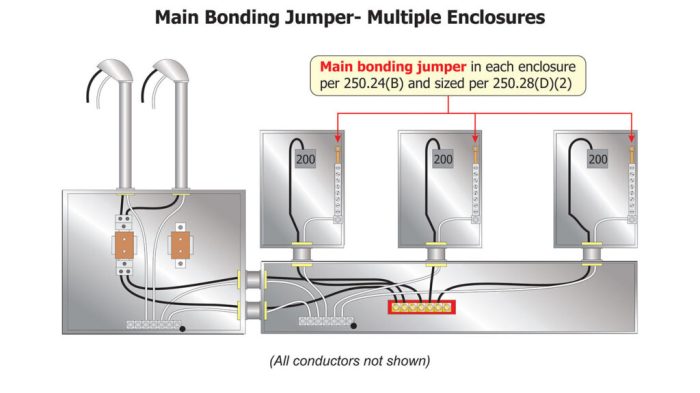

When designing a supply-side bonding jumper, there are several factors to consider, including:

- The size of the electrical system

- The type of electrical system

- The location of the electrical system

- The materials used to construct the electrical system

It is important to consult with a qualified electrician to ensure that the supply-side bonding jumper is properly designed and installed.

Question & Answer Hub

What is the primary purpose of a supply-side bonding jumper?

A supply-side bonding jumper establishes a secure electrical connection between the supply-side neutral and the equipment grounding conductor, ensuring that fault currents are safely diverted to the ground.

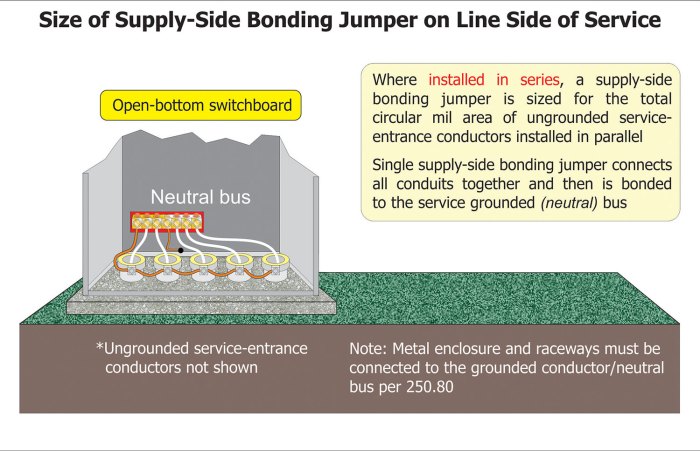

Where are supply-side bonding jumpers typically installed?

As the name suggests, supply-side bonding jumpers are installed at the service entrance, connecting the neutral and grounding conductors before the main breaker or distribution panel.

What are the benefits of using a supply-side bonding jumper?

Supply-side bonding jumpers enhance electrical safety by preventing voltage imbalances, reducing the risk of electrical shocks, and minimizing the potential for equipment damage during fault conditions.

What factors should be considered when designing a supply-side bonding jumper?

The design of a supply-side bonding jumper involves careful consideration of its electrical properties, including voltage rating, current capacity, and impedance, as well as its physical characteristics, such as material, size, and flexibility.